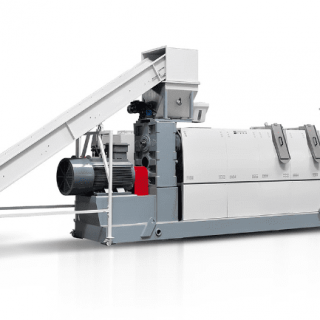

Biomass Wood Chipper with Different Diameter of Processed Raw Materials

The drum chipper is composed of a base, a knife roller, upper and lower feeding mechanisms, a feeding device, a hydraulic buffer system and an electrical control system. It can cut logs, branches and twigs, board peels, waste veneers, bamboo, cotton stalks and other non-wood fiber stalks into chips of certain specifications.

The drum chipper has an advanced structure, high-quality chipped materials and wide adaptability to raw materials. It is convenient to operate and maintain, and can meet the production demands of different scales and types. Its superior performance and wide adaptability make the drum chipper an indispensable important equipment in industrial production.

Chipper Specifications& Models

|

Model |

BSR216 |

BSR218 |

BSR218D |

BSR2110 |

|

Main motor power(KW) |

55 |

110 |

132 |

220 |

|

Main motor start method |

Star triangle |

Star triangle |

Soft start |

Soft start |

|

Blade quantity(pcs) |

2 |

2 |

2 |

2*2 |

|

Infeed Opening Dimensions |

240×540 |

330×680 |

330×780 |

430×1050 |

|

The maximum diameter of the processed raw materials(mm) |

220 |

320 |

320 |

350 |

|

Chip length(mm) |

≤40 |

≤40 |

≤40 |

30/40 |

|

Capacity(T/H) |

4-6T |

10-15T |

12-18T |

35-45T |

|

Feed roller motor power(KW) |

2*3 |

2*4 |

2*5.5 |

2*7.5 |

|

Machine weight(T) |

4 |

7 |

8 |

12.5 |

|

Machine size(m) |

4.4*2.1*1.3 |

4.7*2.2*1.5 |

4.7*2.2*1.5 |

4.9*2.8*1.5 |

|

Technical parameters may be updated, please refer to the latest parameters |

||||

Reviews

There are no reviews yet.