Machining + Turning axis parts

✔ High Precision – Achieves tolerances as tight as ±0.005 in (±0.127 mm). ✔ Excellent Surface Finish – Typically 125–250 µin (3.2–6.3 μm Ra) without additional machining.

Advantages of CNC Turning Milling Axis Parts

1. High Precision

CNC turning milling axis parts can achieve extremely tight tolerances, up to ±0.01mm, ensuring consistency and accuracy in every component.

2. Efficiency

CNC lathes enable efficient mass production, making them ideal for batch manufacturing. The automated process reduces human error and increases productivity.

3. Versatility

These parts can be made from a wide range of materials, including metals like aluminum, steel, and titanium, as well as plastics and composites, allowing for diverse applications.

CNC Turning Milling Axis Parts Process

1. Turning

The primary process involves a cutting tool removing material from a rotating workpiece to create cylindrical or conical shapes.

2. Milling

For complex geometries, milling is combined with turning in multi-axis CNC machines, enabling the production of intricate designs in a single setup.

3. Multi-Axis Turning

This advanced technique allows for simultaneous machining on multiple axes, enhancing precision and reducing the need for multiple setups.

Applications of CNC Turning Milling Axis Parts

1. Shafts & Rods

Used in motors and axles, these parts require high straightness and surface finish.

2. Bushings & Bearings

Ideal for applications requiring tight internal and external diameter tolerances, such as sleeve bearings and spacers.

3. Flanges & Fittings

Components like pipe connectors and hydraulic fittings benefit from precise threading and sealing surfaces.

4. Screws & Fasteners

Bolts, nuts, and threaded inserts are manufactured with exacting thread specifications and knurling.

5. Complex Profiles

Parts like camshafts and turbine blades, which require multi-axis turning and milling, are also produced.

Comparison with Other Methods

|

Turning Method |

Type of Lathe |

Key Features |

Typical Applications |

|

Manual Turning |

Conventional Lathes |

Operator-controlled cutting, less precise, variable quality |

Small batches, prototyping |

|

CNC Turning |

CNC Lathes |

High precision, consistent quality, programmable |

Mass production, high-precision parts |

|

Swiss Turning |

Swiss-type Lathes |

Ultra-precision, ability to machine long slender parts |

Long slender parts, high-precision components |

|

Multi-Axis Turning |

Multi-axis Lathes (with live tooling, Y-axis) |

Can handle complex geometries, multiple operations in one setup |

Complex parts with intricate features |

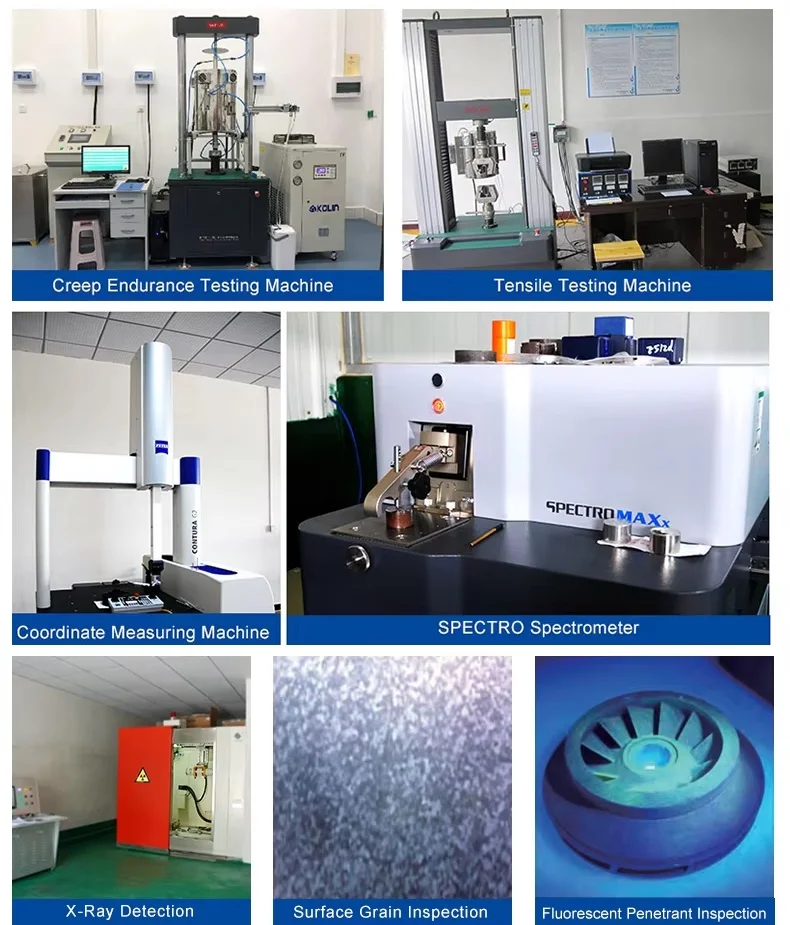

Quality Inspection

Packaging and Shipping

FAQs

How to reduce vibration (chatter) in CNC turning milling?

Use sharp tools with proper rake angles, optimize RPM and feed rates, and employ dampened tool holders or steady rests for long parts.

What' s the best surface finish for CNC turned milled parts?

Roughing: Ra 3.2–6.3 μm (125–250 μin). Finishing: Ra 0.4–1.6 μm (16–63 μin). Superfinishing: Ra <0.2 μm (8 μin) with lapping or grinding post-turn.

How to hold thin-walled parts without deformation?

Use collet chucks for even clamping, machine in multiple passes to relieve stress, and consider magnetic or vacuum chucks for delicate work.

What causes poor surface finish in CNC turning milling?

Tool wear, incorrect speeds/feeds, and improper coolant use can all contribute to poor surface inish.

Reviews

There are no reviews yet.