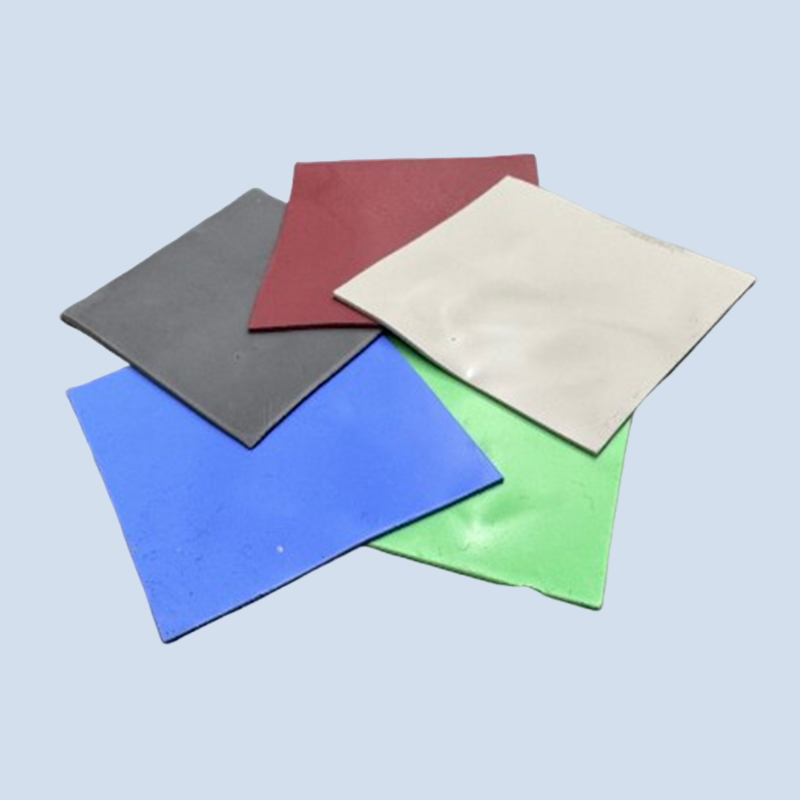

Thermal silicon pad

Thermal conductive silicone pad has certain flexibility, excellent insulation, compressibility and natural viscosity on the surface.

Thermal conductive silicone pad has certain flexibility, excellent

insulation, compressibility and natural viscosity on the surface. It is

specially produced for the design scheme of using the gap to transmit heat. It

can fill the gap and complete the heat transfer between the heating part and the

heat dissipation part. At the same time, it also plays the role of insulation

and shock absorption. It is of great manufacturability and usability, and has a

wide range of thickness application, which can meet the design requirements of

equipment miniaturization and, it is an excellent heat conduction filling

material and is widely used in electronic and electrical products.

Product Features

● Easy manual operation

● The same heat sink can be used for heating devices with different heights

● Low-cost thermal design solution

● Natural viscosity, clean surface, can be repeatedly disassembled and used

● Applicable to automation equipment

● High thermal conductivity, good insulation

Product Application

LED lighting

Backlight module

Switching power supply

Medical equipment

Communication equipment

LED TV

Mobile device

Video equipment

5G network products

Home appliances

PC server/workstation

Base station

|

Test Item |

Unit |

CP100 |

CP200 |

CP300 |

CP400 |

CP500 |

CP600 |

Test Method |

|

|

Color |

/ |

Light Gray |

Gray, Blue |

Grey, Blue |

Green/Dark Gray/Blue |

Pink,dark gray |

dark gray |

Visual |

|

|

Thickness |

mm |

0.15~18mm |

0.2~20mm |

0.3~18mm |

0.3~18mm |

0.3~18mm |

0.3~18mm |

/ |

|

|

Specificgravity |

g/cm3 |

1.9±0.1 |

2.4±0.1 |

2.8±0.1 |

3.2±0.1 |

3.3±0.1 |

3.3±0.1 |

ASTM D792 |

|

|

Hardness |

Shore C |

15~50 |

20~50 |

15~20 |

30~50 |

30~50 |

30~50 |

ASTM D2240 |

|

|

Tensile Strength |

MPa |

≥0.20 |

≥0.2 |

≥0.20 |

≥0.15 |

≥0.10 |

≥0.10 |

ASTM D412 |

|

|

Compressionrate |

% |

15~40 |

15-30 |

10~30 |

20~35 |

20~35 |

20~30 |

ASTM D412 |

|

|

Temperatureresistancerange |

℃ |

-40~+150 |

-40~150 |

-40~+150 |

-40~+150 |

-40~+150 |

-40~+150 |

EN 344 |

|

|

Volumeresistance |

Ω·m |

≥1.0*10^13 |

≥1.0*1013 |

≥1.1*10^13 |

≥1.0*1013 |

≥1.0*1013 |

≥1.0*1013 |

ASTM D257 |

|

|

Withstand voltage |

KV/mm |

≥8 |

≥5.0 |

≥9 |

≥9 |

≥9 |

≥6 |

ASTM D149 |

|

|

Flameretardant rating |

/ |

V-0 |

≥10 |

V-0 |

V-0 |

V-0 |

V-0 |

UL 94 |

|

|

Thermalconductivity |

w/m.k |

1.0±0.1 |

V0 |

3.15 |

4.0±0.4 |

5.0±0.5 |

6.0±0.6 |

ASTM D5470 |

|

|

Oil penetration rate |

% |

≤1.0 |

2.0±0.2 |

≤1.0 |

≤1.0 |

≤1.0 |

≤1.0 |

ASTM G120 |

|

Test Item |

Unit |

CP700 |

CP800 |

CP900 |

CP1000 |

CP12000 |

CP15000 |

Test Method |

|

Color |

/ |

Dark Gray |

Dark Gray |

Dark Gray |

Dark Gray |

Dark Gray |

Dark Gray |

Visual |

|

Thickness |

mm |

0.3~18mm |

0.3~18mm |

0.5~5mm |

0.5~5mm |

0.5~5mm |

0.5~5mm |

/ |

|

Specificgravity |

g/cm3 |

3.3±0.1 |

3.4±0.1 |

3.4±0.1 |

3.4±0.1 |

3.4±0.1 |

3.5±0.1 |

ASTM D792 |

|

Hardness |

Shore C |

35~50 |

35~50 |

35~50 |

35~50 |

35~50 |

35~50 |

ASTM D2240 |

|

Tensile Strength |

MPa |

≥0.10 |

≥0.10 |

≥0.10 |

≥0.10 |

≥0.10 |

≥0.10 |

ASTM D412 |

|

Compressionrate |

% |

5~20 |

5~15 |

5~15 |

5~15 |

5~20 |

5~15 |

ASTM D412 |

|

Temperatureresistancerange |

℃ |

-40~+150 |

-40~+150 |

-40~+150 |

-40~+150 |

-40~+150 |

-40~+150 |

EN 344 |

|

Volumeresistance |

Ω·m |

≥1.0*10^13 |

≥1.0*10^13 |

≥1.0*10^13 |

≥1.0*1013 |

≥1.0*1013 |

≥1.0*1013 |

ASTM D257 |

|

Withstand voltage |

KV/mm |

≥6 |

≥6 |

≥9 |

≥7 |

≥6 |

≥6 |

ASTM D149 |

|

Flameretardant rating |

/ |

V-0 |

V-0 |

V-0 |

V-0 |

V-0 |

V-0 |

UL 94 |

|

Thermalconductivity |

w/m.k |

7.0±0.7 |

8.0±0.8 |

9.0±0.9 |

10±1.0 |

12±1.2 |

15±1.5 |

ASTM D5470 |

|

Oil penetration rate |

% |

≤1.0 |

≤1.0 |

≤1.0 |

≤1.0 |

≤1.0 |

≤1.0 |

ASTM G120 |

Reviews

There are no reviews yet.