Rubber Grommet

After 30 years, five locations, and three generations of hard work, ZLR successfully maintained the core values established in 1993 with a full commitment to employees, customers, and the community.

Advantages of High Temperature Rubber Grommets

– Superior Thermal Stability: They maintain mechanical properties and flexibility regardless of temperature changes .

– Resistance to Harsh Conditions: They resist oxidation, thermal aging, and degradation for improved longevity .

– Substance Resistance: High temperature rubber grommets protect against exposure to oils, chemicals, and fuels .

– Reliable Flexibility and Resilience: These materials resist deformation and mechanical stress, keeping them in working condition when used in high-temperature environments for long periods .

– Weather Resistance: They provide excellent resistance for indoor & outdoor use .

– Longer Durability & Tear-Resistant: High temperature rubber grommets are known for their long-lasting durability and resistance to tears .

– UV Light & Ozone Resistance: They offer great resistance to UV light and ozone .

– Quick & Easy to Install: High temperature rubber grommets are designed for ease and speed of installation .

Features of High Temperature Rubber Grommets

– Material Composition: They are made from polymers that optimize performance and heat resistance while maintaining their core properties .

– Temperature Range: High temperature resistant rubber materials can operate in a wide range of temperatures, with some materials like silicone rubber resisting temperatures up to 300°C (572°F) .

– Physical Properties: They combine the characteristics of both inorganic and organic materials, making them superior to conventional organic rubber in terms of high temperature resistance, low temperature resistance, oxidation resistance, and more .

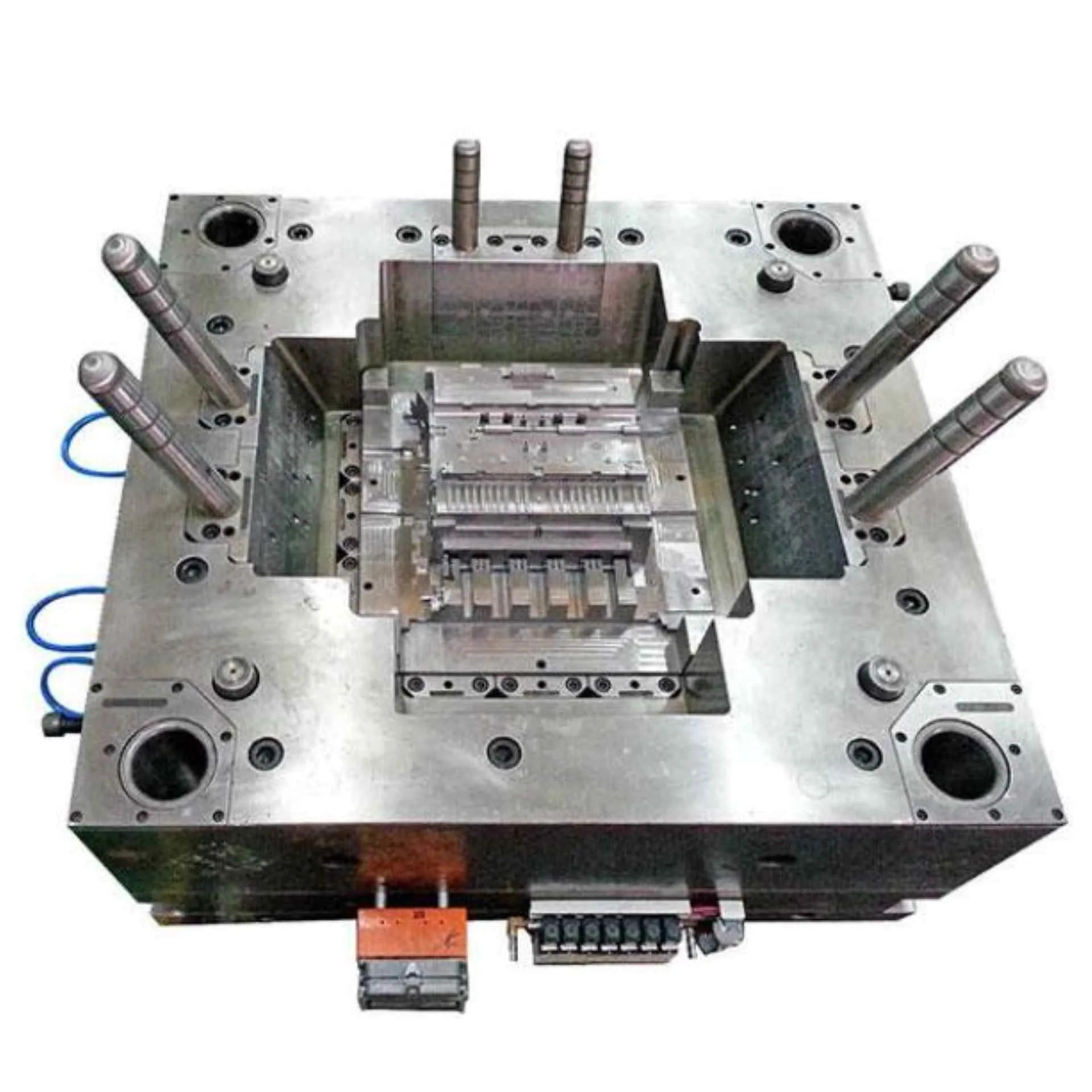

Manufacturing Process of High Temperature Rubber Grommets

The manufacturing process of high temperature rubber grommets involves several key steps:

– Compounding: Raw rubber is mixed with various chemical additives to enhance its properties for specific applications .

– Molding: The rubber material is molded into the desired shape using compression, injection, or transfer molding techniques .

– Metal Preparation: For rubber-to-metal bonded grommets, metal sleeves or shells are prepared, and their surfaces are treated to ensure strong adhesion to the rubber .

– Bonding Process: In the case of bonded and rubber-to-metal bonded grommets, the rubber is related to the metal using adhesives and curing processes .

– Finishing: The rubber grommets are trimmed, inspected for quality, and any necessary finishing touches are applied .

Applications of High Temperature Rubber Grommets

– Industrial Machinery: Used to reduce noise, vibrations, and friction, extending the lifespan of moving parts and ensuring smooth operation .

– Marine Applications: Minimize vibrations and prevent metal-to-metal contact in harsh marine environments .

– Construction and Infrastructure: Used in building foundations, bridges, and infrastructure to isolate vibrations and provide flexible connections .

– Aerospace: Critical for providing thermal insulation materials for gaskets and seals, maintaining propulsion and fuel systems in demanding environments .

– Electronics: Used for electrical insulation and protection of cables and wires passing through solid panel walls .

– Automotive: For weather stripping, seals, wire and cable harnesses, and more .

ZLR as a heat resistant rubber grommets exporter and provider. Our high-quality high temperature rubber grommets for sale are worthy of your trust. Welcome to consult us!

Reviews

There are no reviews yet.